Pro One Softfall has been creating safe, dynamic, creative, softfall rubber spaces since 1996. We have a tight-knit team of experts who can help you with your recreational area. Pro One has a genuine interest in providing our clients access to advanced technology and design that facilitates premium performance, optimal usage and extended life on their construction projects. Our staff take pride in the high quality of their work, but also assist their clients in design, suggestions on drainage, transitions, levels etc. We are happy to meet our clients for site inspections at any stage of the project, or alternatively will gladly represent our clients on-site in a professional manner to ensure the job is completed on time and on budget seamlessly.

Reliability

You can depend on Pro One. When we take on a project we take it very seriously. We know that your client is relying on you to complete the project on time and on budget and it’s imperative that we represent you with the greatest quality of work and professionalism possible.

Quality

Quality is what we do best, our large team have all the different skill sets we need to deliver a high quality project. We enjoy seeing projects come to life and take pride in delivering a high quality safe product.

Services

We realise a project doesn’t just end at handover. It’s essential to ensure that the space remains safe and compliant for the life of the installation. Pro One document all aspects of the project and are available to help at a moments notice should you require assistance even years after project completion.

Environmental Sustainability

A large number of Australia’s end-of-life tyres are being disposed through landfill, stockpiles, exported as baled tyres or illegally dumped. The Federal Government’s Hyder report has estimated that 51 million tyre equivalent passenger unit (EPU) tyres reached their end of life in Australia in 2013-14. Unfortunately a lot of these are illegally dumped or end up in our landfill.

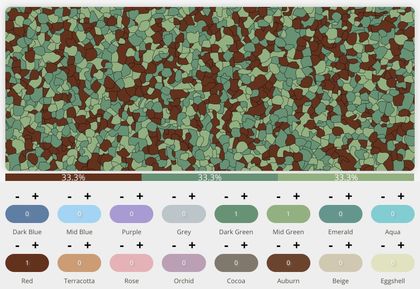

Pro One is keen to protect the environment as much as possible so wherever we can we use recycled rubber products. Most of our rubber jobs use CSBR rubber which is recycled car tyres granulated, cleaned, then put through a process which adds the colouring. Using recycled not only saves the problem of disposal, there’s also a huge energy saving benefit. Making 1kg of rubber product from recycled tyres saves about 75% of the energy needed to produce 1kg of virgin rubber.

Below are a couple of case studies we’ve done on how much using these recycled products helps the environment.

Saving our environment for future generations

Case Study One: Hawthorne Park, Brisbane

The Hawthorne Park Brisbane project used CSBR recycled rubber and rubber mulch impact cushioning which considerably benefited the environment over using virgin rubber product.

7855

Kilograms of Rubber used

1123

Car tyres saved from landfill

60091

Litres of landfill space saved

Saving our environment for future generations

Case Study Two; Stapyltons Road, Heathwood

Our client was after a solution where the centre median strips on Stapyltons Road, Heathwood required surfacing which would allow water to flow through to tree roots of the newly planted vegetation and yet wouldn’t wash away or affect the roadways like bark mulch might do. Pro One designed a recycled rubber mulch solution which satisfied Council arborists and traffic planners.

9000

Kilograms of Rubber used

1287

Car tyres saved from landfill

68850